Preventive maintenance of ships is essential to ensure the safety, efficiency and longevity of vessels. Adopting a structured inspection and...

In this article, we present a selection of essential terms that facilitate understanding of the operations, systems, and structures associated with naval engineering and maintenance. This is a useful resource for both professionals and those curious about the workings of shipyards.

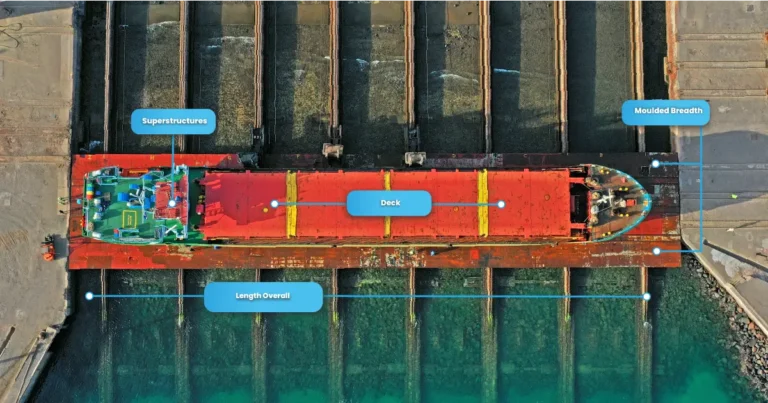

Before delving into technical terminology, it is important to visualise the basic structure of a ship. The cover image of this article, captured by drone, shows a ship in dock with some structural elements highlighted.

Terms highlighted in the image:

– Length Overall (LOA): total measurement of the ship, from the bow to the stern.

– Moulded Beam: maximum width of the hull, measured between the inner points of the cavities.

– Deck: main visible floor of the vessel, which may be divided into several sections depending on the function and type of ship.

– Superstructures: structures located above the main deck, such as the bridge, accommodation or technical compartments.

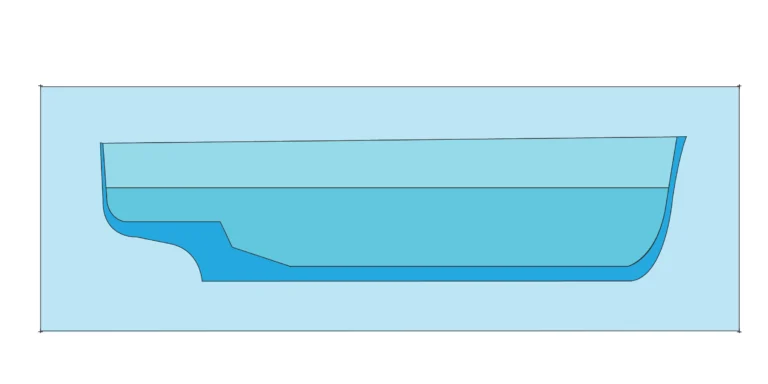

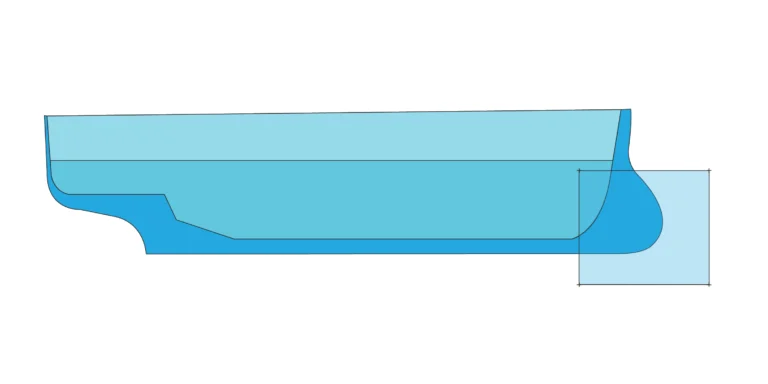

Hull – The outer part of the vessel that remains in direct contact with the water. It can be constructed from steel, aluminium or composite materials, depending on the type of ship.

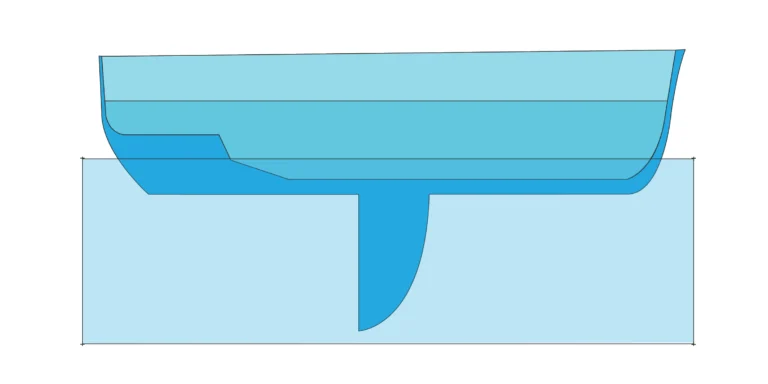

Keel – Structural element that provides stability to the hull.

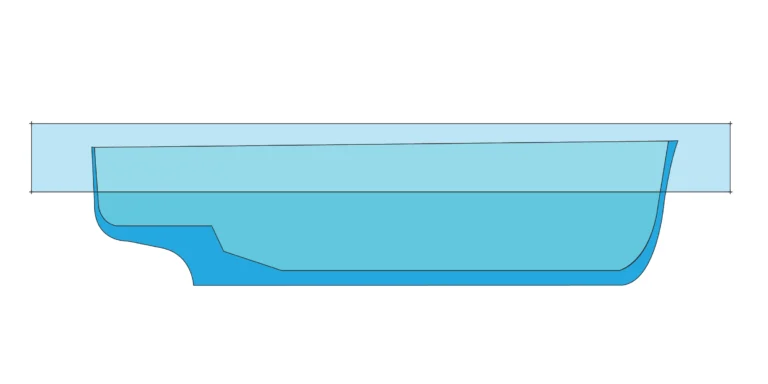

Freeboard – Distance between the waterline and the main deck.

Bow bulb – A rounded extension at the front bottom of the hull that improves hydrodynamic efficiency.

Docking – The process of placing a ship in dry dock for maintenance.

Beaching – Moving a vessel sideways onto dry land.

Stowage – Organisation of cargo on board.

Mooring – Manoeuvring the ship alongside the quay.

Towing – Pulling one ship with another.

Hydrojet – Cleaning the hull with a high-pressure water jet.

Naval welding – Joining structural metal elements.

Steel work – Manufacturing and repairing metal structures.

Machining – Lathe, milling and finishing processes for metal parts.

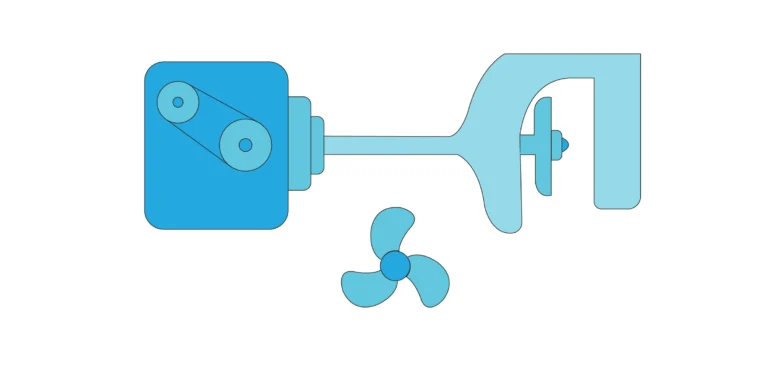

Main engine – Responsible for propelling the ship.

Propeller – Device that converts engine power into motion.

Steering gear – Manoeuvring system, including the rudder and controls.

LPP (Length Between Perpendiculars) – Length between perpendiculars at the bow and stern.

Gross Tonnage (GT) – Total internal volume of the ship.

Net Tonnage (NT) – Useful volume for cargo and passengers.

Displacement – Weight of displaced water, equivalent to the weight of the ship.

Draft – Height between the keel and the main deck.

Antifouling – Coating that prevents the growth of marine organisms.

Primer – Base coat that protects against corrosion.

DFT (Dry Film Thickness) – Dry thickness of the applied paint.

Freeboard – Distance between the maximum load line and the main deck.

Watertightness – Ability to prevent water from entering.

Class certification – Document proving technical and structural compliance.

Engine room – Space containing engines and propulsion systems.

Rudder – Submerged steering structure.

Superstructure – Part of the ship above the main deck.

Knowledge of technical naval terminology goes beyond internal communication: it is a key factor for safety, efficiency and quality in the execution of services. Understanding these concepts allows you to:

– Reduce communication failures between customers and shipyards;

– Clearly interpret technical reports, budgets and repair plans;

– Monitor ongoing interventions with greater accuracy;

– Raise the technical and professional level of all stakeholders.

CABNAVE is committed to promoting technical knowledge and the continuous training of its team. We believe that sharing information is essential for the development of the naval sector in Cape Verde.

Continue to follow our Technical Blog, where we discuss topics related to maintenance, innovation, and best practices in ship repair.

Do you have questions about a technical concept or would you like to see a term included in a future edition?

Please contact us using the contact form. We are always available to clarify any questions.

Preventive maintenance of ships is essential to ensure the safety, efficiency and longevity of vessels. Adopting a structured inspection and...

The choice of a technical shipyard is a determining factor in the quality and reliability of ship repair and maintenance...

Preventive maintenance of ships is essential to ensure the safety, efficiency and longevity of vessels. Adopting a structured inspection and...

A ship's longevity and performance are directly linked to the quality of the technical inspections carried out throughout its life...

Share with industry professionals: